The maximum flow rate of the A4VG125 pump is 125 liters per minute (LPM), although the actual flow rate can vary depending on the specific application.

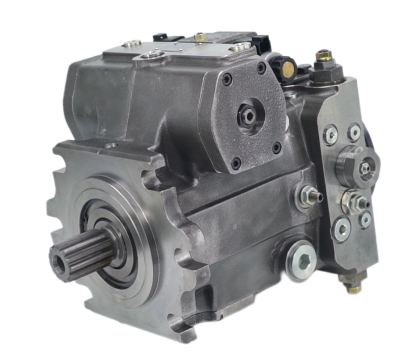

The A4VG125 pump is designed with axial pistons that are arranged in a swash plate configuration. The pump also features a built-in pressure relief valve and a through-drive option for multiple pump configurations.

It has various control options, including hydraulic, electric, and electronic control. Which is commonly used in industrial machinery, including excavators, cranes, and other construction equipment. It can also be used in marine and offshore applications, as well as in wind turbines and other renewable energy systems.

Regular maintenance of the A4VG125 pump is important to ensure its performance and longevity. Some general steps that may be involved in repairing an A4VG125 pump:

Disassembly: The first step is to disassemble the pump and inspect its components. This may involve removing the swash plate, pistons, and other parts of the pump.

Cleaning and inspection: Once the pump is disassembled, the parts should be cleaned thoroughly and inspected for wear, damage, or other issues. Any worn or damaged parts should be replaced.

Reassembly: After inspecting the pump, it is time to reassemble it. This may involve replacing seals and gaskets and installing new components as needed.

Testing: Once the pump is reassembled, it should be tested to ensure that it is functioning properly. This may involve checking the flow rate and pressure of the pump, as well as inspecting it for leaks or other issues.

It is important to note that repairing an A4VG125 pump can be complex and may require specialized tools and equipment.